Flat Return Idler – GCS Conveyor Roller Provider

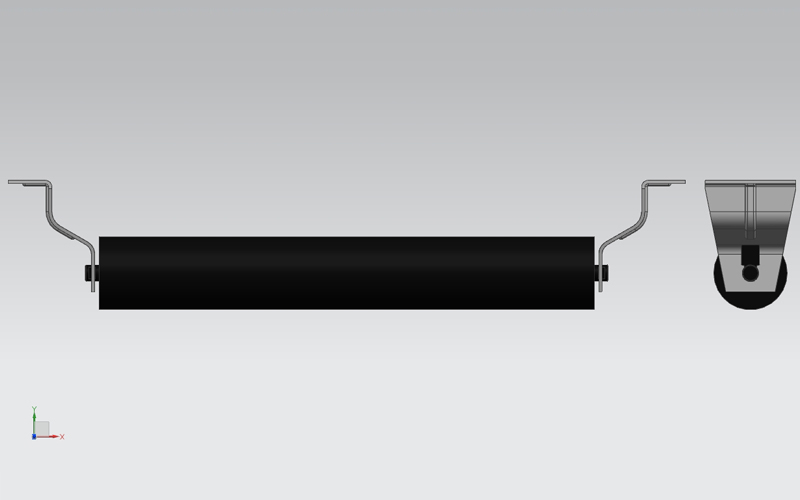

Conveyor Belt Roller Manufacturers of Return Idler

Wholesale conveyor belt rollers and conveyor roller components have an extensive history of durability and high performance in the most abrasive material handling applications. From impact to return idlers and everything in between, GCS Conveyor Belt Roller Manufacturers has you covered, no matter where or what your belt conveyor is moving.

Material pipe: Q235 Carbon steel

Shaft: A3 cold-down shaft,zzC3 Chinese bearing

Finish: roller face and ends to be painted black

Bandwidth specifications (mm) 400-3000

Pipe diameter specification (mm) 63.5-219

Flat Return Idler Series

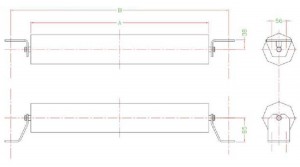

SERIES LS/RS 102 Dia. & SERIES RS/HRS 127 Dia.

SERIES LS/RS 102 Dia. & SERIES RS/HRS 127 Dia.

FLAT CARRY AND RETURN IDLER-178 DIAMETER

| Code No. | A | B | Series 50 | Series 60 | ||||

| Shaft Dia. | Mass R.P. | Total Mass | Shaft Dia. | Mass R.P. | Total Mass | |||

| XX-A1-1-K0E2-0900-YY | 1002 | 1150 | 38 | 26.5 | 40.5 | N/A | N/A | N/A |

| XX-A1-1-K0E2-1000-YY | 1102 | 1250 | 38 | 28.9 | 43.8 | 32.5 | 53.4 | |

| XX-A1-1-K0E2-1050-YY | 1152 | 1300 | 38 | 30.1 | 45.4 | 48 | 33.8 | 55.4 |

| XX-A1-1-K0E2-1200-YY | 1302 | 1450 | 38 | 33.7 | 50.4 | 37.6 | 61.4 | |

| XX-A1-1-K0E3-1350-YY | 1502 | 1650 | 42 | 39.0 | 60.5 | 48 | 42.7 | 69.3 |

| XX-A1-1-K0E3-1400-YY | 1552 | 1700 | 42 | 40.3 | 62.4 | 44.0 | 71.3 | |

| XX-A1-1-K0E3-1500-YY | 1652 | 1800 | 42 | 42.7 | 65.9 | 48 | 46.5 | 75.3 |

| XX-A1-1-K0E5-1600-YY | 1852 | 2000 | 45 | 47.7 | 76.1 | 51.6 | 83.2 | |

| XX-A1-1-K0E5-1800-YY | 2052 | 2200 | 45 | 52.7 | 83.8 | 48 | 56.7 | 91.1 |

XX-input for: RS or HRS.

For flat carry idlers, replace E with H.

For alternative return drop heights, refer to the identification system.

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

1.What is a return idler?

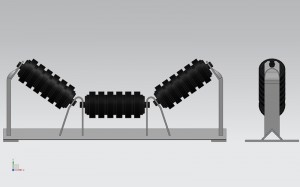

Return idlers are used to support the belt as it cycles around to be loaded again.

2.What types of idler are there?

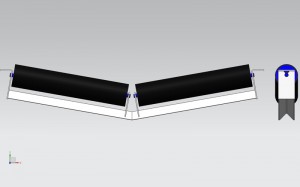

In summary, the four most commonly used types of idlers are trough idlers, flat return idlers, impact idlers and training return idlers.

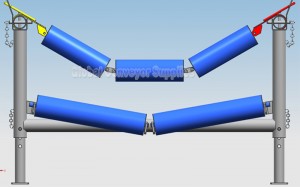

3.What is a troughing idler?

A troughing idler is comprised of a central idler roll, which has a fixed width, and two or more wing idlers located on each side of the central idler roll. The wing idlers can be adjusted up or down to change the toughing angle, which affects the depth of the trough created by the conveyor belt as it moves.